Responsible value chain

Operational excellence

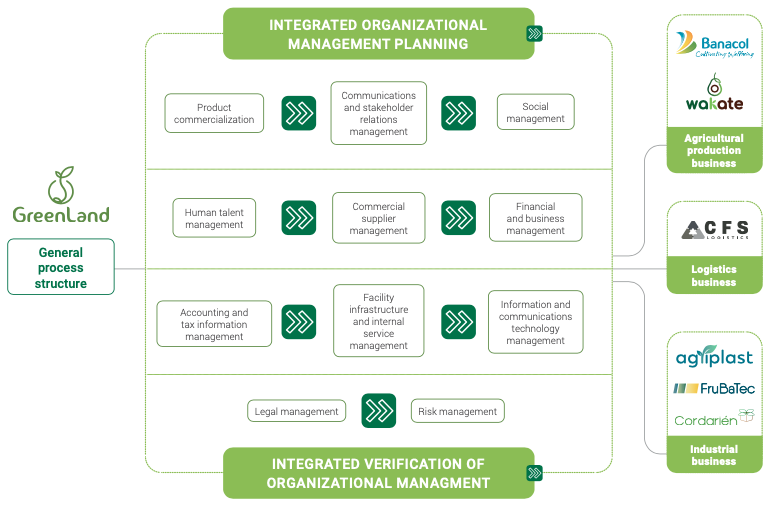

We have internalized a management approach that starts with planning,

competitive quality-based execution, and process and resource control aimed at operational maturity and excellence. We manage each business independently and are vertically integrated based on the efficiencies we have implemented and overarching corporate processes, trying for alignment as a group and the specialization of each business line.

Process Map

Outside initiatives

Certifies our activities to protect the ecosystems and natural resources (flora, fauna, soil, and water), and our use of good environmental and social practices, the use of phytosanitary products, and proper waste disposal.

Certifies our activities to protect the ecosystems and natural resources (flora, fauna, soil, and water), and our use of good environmental and social practices, the use of phytosanitary products, and proper waste disposal.

Certifies our integrated pest and cultivar management within the agricultural production framework. Our commitment to our clients is to provide excellent products that meet their standards for consumption.

Certifies our integrated pest and cultivar management within the agricultural production framework. Our commitment to our clients is to provide excellent products that meet their standards for consumption.

A social standard that promotes improving work conditions, quality of life, and the wellbeing of our team and their families. Banacol’s corporate policy is to not hire minors, and not to discriminate by reason of races, sex, age, origin, nationality, religion, sexual orientation, or political affiliation, among others.

A social standard that promotes improving work conditions, quality of life, and the wellbeing of our team and their families. Banacol’s corporate policy is to not hire minors, and not to discriminate by reason of races, sex, age, origin, nationality, religion, sexual orientation, or political affiliation, among others.

Our logistics operation is certified under BASC (Business Coalition for Safe International Trade), an international alliance that promotes safe international trade in cooperation with governments and international bodies.

Our logistics operation is certified under BASC (Business Coalition for Safe International Trade), an international alliance that promotes safe international trade in cooperation with governments and international bodies.

Our port facilities in Nueva Colonia and Zungo are certified under the international ISPS – International Ship and Port Facility standard, aimed at establishing and implementing appropriate safety conditions for our port terminal employees. In 2021, this certification was granted until September 2025.

Our port facilities in Nueva Colonia and Zungo are certified under the international ISPS – International Ship and Port Facility standard, aimed at establishing and implementing appropriate safety conditions for our port terminal employees. In 2021, this certification was granted until September 2025.

Production

AÑO 2020

AÑO 2021

We work every day with our more than 4000 employees to meet the expectations of our clients through carefully grown and harvested high-quality products, that enable us to be competitive and maximize our results.

Some figures

As part of our quality assurance strategy, we made our process more technical looking for greater efficiency in the post-harvest camera operations.

56 electronic scales to determine the net weight of fruits in trays were installed for all our farms, thus ensuring that we keep our promise to the clients.

Fertilizer consumption: Organic fertilizers: 30,227,056 kg Organic liquid fertilizers: 657 L Synthetic fertilizers: 29,266,540 kg Liquid synthetic fertilizer: 38,638 L

In 2021 we planted 1,248 ha of noble cover.

The characteristics of our soil make it possible to use a large amount of cover, which helps reduce the use of herbicides. Total herbicide consumption: 75.1 m3

In our aerial spray operations for Sigatoka control, we provided training to the crews which, together with optimized processes and precision technology, helped us save materials and increase the number of hectares per hour for the planes, and fuel per hectare, as part of our effort to mitigate carbon emissions and environmental impact.

As part of our quality assurance strategy, we made our process more technical looking

for greater efficiency in the post-harvest camera operations.

56 electronic scales to determine the net weight of fruits in trays were installed for all our farms, thus ensuring that we keep our promise to the clients.

Fertilizer consumption:

Organic fertilizers: 30,227,056 kg

Organic liquid fertilizers: 657 L

Synthetic fertilizers: 29,266,540 kg

Liquid synthetic fertilizer: 38,638 L

In 2021 we planted 1,248 ha of noble cover.

The characteristics of our soil make it possible to use a large amount of cover, which helps reduce the use of herbicides

Total herbicide consumption: 75.1 m3

In our aerial spray operations for Sigatoka control, we provided training to the crews which, together with optimized processes and precision technology, helped us save materials and increase the number of hectares per hour for the planes, and fuel per hectare, as part of our effort to mitigate carbon emissions and environmental impact.

Some figures

We bought an additional ha for cultivation.

We implemented a fumiduct system

We look for the best allies

Supply chain management

Purchases

from suppliers

- 54% Fruit

- 2% Transportation

- 11% Inter Company purchases

- 16% Services

- 17% Goods

Our challenges

GreenLand

- Strengthen our socioenvironmental connection with our suppliers of national and international goods and services, sharing with them the principles of sustainability, and promoting their implementation and application.

Banacol, Wakate, CFS Logistics, Control B, Agriplast

- Strengthen close ties with our clients, sharing the principles of sustainability and measuring their perception and satisfaction with our service.

Banacol

- Use 26,000 tons of fruit that was not exported to create added value for our new business of production and commercialization of banana flour and purée, Frubatec.

- Benefit 11,000 people in our communities by donating banana flour.

Agriplast

- 98% of the material we collect in our field work will be recycled in the plastics factory. In addition, 30% of the propylene for producing rope will be recycled.

CFS Logistics

- Guarantee 100% reuse of our waste material (straps, cardboard, oil, and other materials).

GreenLand

- Propose, align, and follow-up on the service levels of corporate support provided to the companies in the Group.

Banacol

- Implement a system to densify irrigation for 200 ha of banana plants.

- Decrease the chemical load in our crops. For next year, increase by 5% the native noble cover, equivalent to 500 ha. Mechanical weed control will be used for this purpose.

Wakate

- Finish planting 150,000 avocado trees in the Entre Arroyos farm, in 172 hectares for new production.

- Implement the second production bloc by planting 250,000 trees in 450 hectares for production.

- Start operation of the fumiduct for the first 850 hectares and implement the system for 387 hectares of production.

- We will harvest 143,000 trees planted during 2020.

- Finish planting 150,000 avocado trees in the Entre Arroyos farm, in 172 hectares for new production.

CFS Logistics

- We are constantly updating our information systems to improve the efficiency of our fruit handling processes.